In fact the production management software or Material Requirements Planning (MRP software) includes planning, implementation and monitoring of production, in this direction, several planning models are designed and used. Each of the models has its own advantages and disadvantages and has different efficiency according to the desired industry.

This process requires coordination and supervision of people, materials and equipment. Also, this process requires managers to continuously make decisions in four main areas.

A) Production Plan

Improving the equipment maintenance process:

Without effective management of production processes, more errors and inefficiencies are observed in the factory. There are other reasons why production management is important to business operations.

Reduce Production Cost:

By maximizing outputs while minimizing inputs, production management software (MRP software) reduces the cost required to produce finished products, which can be used to improve profit margins.

Improving the Competitive Level:

Knowing that products are available on time and delivered on schedule means that a company is always competitive and selling in any market.

B) Fulfillment of Business Goals

Production management software (MRP software) helps companies to produce finished goods in stock faster. Because these end products are always made to high quality and delivered on time, businesses can use these to grow their business, provide capital for development, and increase customer satisfaction.

C) Improving the Brand Image

Nowadays, brand and brand image have become very important. Brand management means that customers trust the products and can be sure of their quality and availability, thereby improving the brand image.

D) Optimal Use of Resources

Production management (MRP) means that labor, equipment and resources are optimized in production. This can reduce production waste and create an environment for employees that is positive and balanced. With today’s emphasis on work-life balance and green initiatives to reduce carbon footprints, effective production management that optimizes resource use can help realize both of these trends.

What is the production and operations management module (MRP software)?

While these two cases are seamlessly connected. But there is a difference between production and operations management. In each factory, the production manager applies management principles specifically to the production process. On the other hand, the role of operations management is broader as it relates to business activities outside of production as well.

Operations managers use business management principles to ensure that the entire organization, not just production, runs smoothly and efficiently. This includes not only direct input into the production process. It also includes service responsibilities that may be associated with production.

Such as customer service or field service. Operations management also includes warehouse inventory and supply chain and may manage other departments as well. Other functions related to operations management include:

Strategic Plans

In fact, operations management is done in order to ensure the creation of effective strategies to maximize all the capacities of the company simultaneously.

Financial Department

Operations management is often involved in budgeting and capital and operational planning.

Product Design

Basically operations managers are responsible for ensuring that the products produced by the factory can be produced at optimal cost.

Forecasting

Operations management is a bridge between sales and production and may have the task of forecasting the products and services needed in the future. Operations management and production management have different scope, focus and organizational structure in terms of meaning.

If there is a need of the organization and a higher maturity level of the production process and production control in the organization. In addition to material planning, there is a need to plan and control manpower, machines and details of each work station, another tool to achieve this goal is MRP II software.

Using the production requirements planning engine naturally requires a higher level of maturity in the organization with very high complexity in implementation. This tool is used to select leading and successful organizations in the world to manage production planning and control.

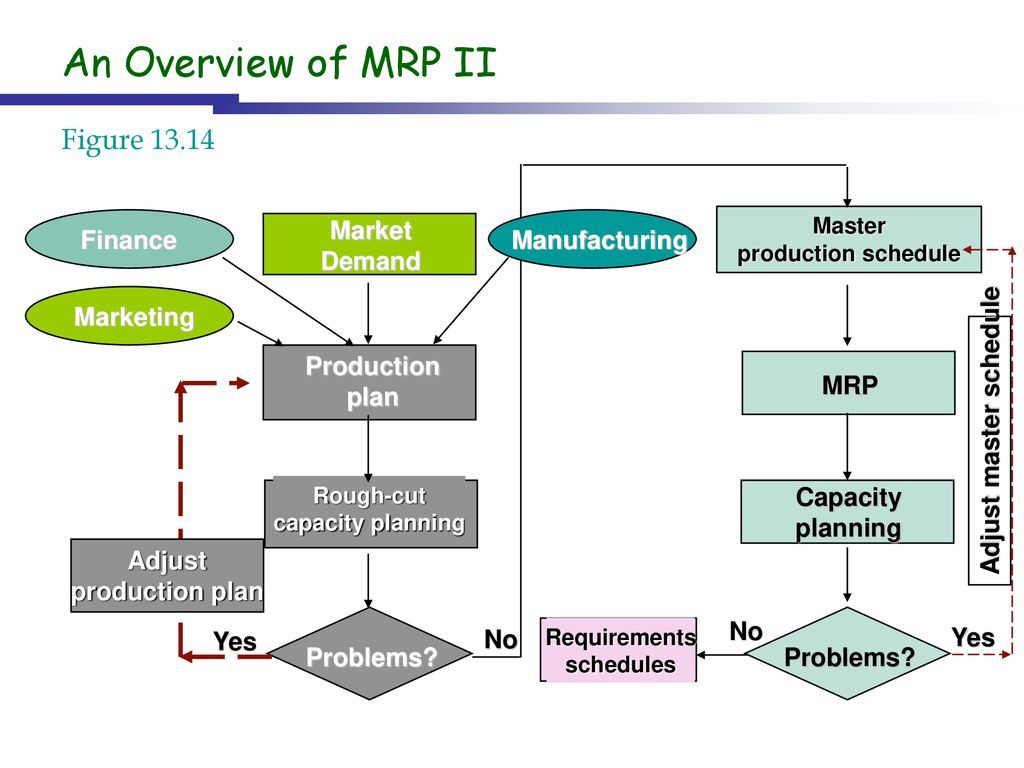

What is MRP II software and what are the benefits of production management software?

MRP II software is an expanded model of MRP, in which other than planning of the required raw materials, it manages and plans for the planning of manpower and machines. It also manages all the factors affecting production. This method is mainly done through production management software and special software is designed for this purpose.

In this system, data such as raw material data, such as the product tree and production line data, such as workstations, work shifts, production routes, personnel of each workstation, etc. are defined for the software and other data from such as customer orders or product sales forecast in the desired time period, we enter in the software.

According to the MRP II method, the production management software processes these data and outputs the required raw materials, required machines, required personnel and the time required to produce each order separately or aggregated as soft output. The software is provided to the person in charge of production or management.

The role of MRP system in organizations:

The production resource planning (MRP) system plays an important role in organizations. This system helps organizations to efficiently manage the production, distribution and purchase of raw materials and finished products. Following are several key roles of MRP system in organizations:

1. Inventory Optimization:

The MRP system helps organizations to manage their inventory efficiently. This system can predict demand for raw materials and help organizations buy only the required amount.

2. Production Planning:

MRP system helps organizations to optimize production planning. This system can predict the demand for finished products and help organizations to adjust their production based on this demand.

3. Reducing Costs:

By optimizing inventory and production planning, an MRP system can help organizations reduce costs. This system can help organizations reduce costs related to inventory holding and inefficient production.

4. Improving Customer Service:

By ensuring that products are produced and delivered on time, an MRP system can help organizations improve their customer service.

5. Strategic Decision Making:

MRP system can provide useful information for strategic decision making. Using this information, organizations can make important decisions about production, purchasing, and distribution.

Advantages of production management software:

- Record and maintain the formulas for making semi-finished goods and finished products.

- Manage the production planning of semi-finished products and final products in different time frames.

- Easily manage the tracking of raw materials and the control of production batches.

- Manage the planning of required raw materials and supply of production lines and inventory of working materials.

- Manage the inventory of sensitive and expired raw materials and how to use them correctly.

- Control and manage consumption deviations for production and waste of raw materials.

- Manage the planning and control of manpower required in production lines.

- Manage the entire production process and control the production lines.

Benefits of production management in manufacturing

Effective production management is critical in today’s manufacturing environments, and without it, operations cannot meet commitments or profit goals. But with production management, companies can receive various benefits regardless of the size of the organization. These benefits include the following:

- better quality

- Less production waste

- Low operating cost

- Better decision making

We at Ilia have created the ability to support this software with maximum reliability by the technical team within the company by providing a valid license in the name of your organization from Focus Company and by institutionalizing the technical knowledge of this software in our company.

What is the definition of production management software (MRP software)?

Production management software solutions are not a new concept. But as we enter the digital age, companies have access to tools they couldn’t use before. Production management software can take the system described above to the next level, and to improve all processes by identifying deeper levels of data that can be turned into improvements. It also automates many functions, which reduces both human error and time.

Awards Received by Focus ERP in 2021

Advantages of using production management software (MRP software) in organizations:

- Reducing costs in all units of the organization, such as reducing the costs of using sheets, inventory control, human resources costs, production costs, accounting operations costs and recording financial information, etc.

- Increasing the speed and efficiency in the organization’s processes

- Quick, easy, online and accurate access to data at the management and employee level

- Increasing the agility of management and decision-making teams in facing the crisis

- Standardization of processes according to global standards

- Detailed planning in the short, medium and long term

- Creating the integrity and coherence of information, data and reducing the contradiction with the existing reality

- Creating coordination and speed of intra-organizational cooperation between different units, reducing work interruptions and increasing efficiency

- Improving teamwork

- Simplifying processes

- Reducing IT costs, support, consulting and user training

- Accurate rooting of the organization’s problems

- Get performance statistics separately for each unit, cost center, personnel or device

- Increasing security and access rights at the user level

- The ability to record or display information from anywhere in the world

- Increasing customer and contractor satisfaction

- Improving timely delivery

- Obtaining the exact cost of products or services

- Improving the production cycle and reducing stoppages

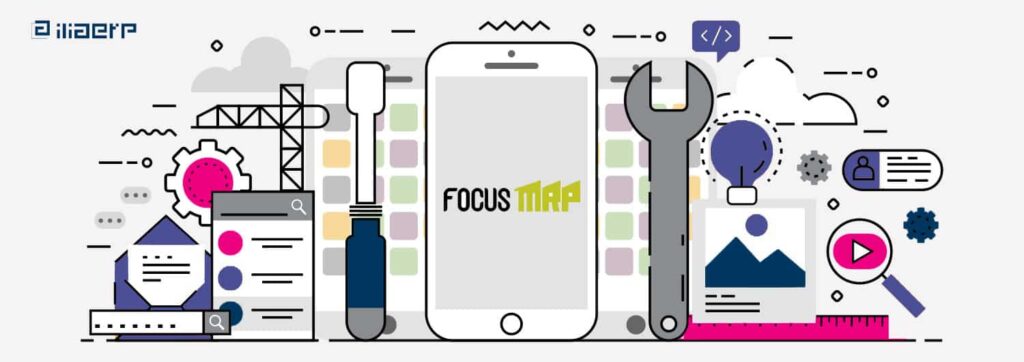

Focus MRP production management software:

Focus MRP software has limited and unlimited planning capabilities that help complex production processes to increase the effectiveness of activities and customer satisfaction. It doesn’t matter if you have one or more factories, this integrated solution with its scalability is an advantage for all manufacturers.

Advantages of Focus MRP production management software:

- Ability to minimize production bottlenecks

- The possibility of improving transparency and better control of operations

- The possibility of planning or forecasting orders based on production to increase profitability

- Ability to identify and plan human resource skills or equipment resources for workstations

- The possibility of scheduling the production of products based on the capacity of the workshop

- The possibility of analyzing the material requirements online and announcing the material requirements for the necessary production supplies to the purchasing unit.

- Ability to create reports based on forecast, process or production steps

- Designed by Net platform and using MS-SQL database

- Full integration with other ERP modules

- The possibility of activating software programming interface (API)

- Ability to support workload balance between servers in multi-layer architecture

- The possibility of cost reduction and better use of resources

- The possibility of improving customer satisfaction with timely delivery of goods

- Ability to define calendars for different locations considering working hours

- The possibility of supporting standard production with the path of the production process defined in the production lines

- Possibility of forecasting production order and production capacity based on reports

- The possibility of defining the product/goods/raw materials/semi-finished goods

Also:

- Ability to define production resources

- The possibility of drawing the production process graphically

- Ability to define workstations

- Ability to define capacity

- The possibility of analyzing the progress of goals

- Ability to analyze price queries

- Ability to manage supplier contracts

- Material requirements planning

- Ability to plan material requirements for planned orders and forecasts

- The possibility of planning for the needs of independent and dependent materials

- The possibility of sending and transferring raw materials and goods to production units

- Workshop management

- The possibility of analyzing the discrepancies that have arisen

- The possibility of reporting on the completion of warehouse inventory

- Shift management

- Ability to update production cost including overhead costs

- The possibility of management based on the just-in-time or JIT method

Ilia ERP Corporation has a brilliant history in implementing and consulting on ERP software in order to provide the best possible services to customers, and provides the following services:

Consulting and ERP implementation

Free consultation and troubleshooting for organizations

Identifying process problems and helping to solve them

Providing free services regarding systemization and team management

Identifying points of improvement in organizations and helping to save or increase income in susceptible areas

Also, you can use up to 10 hours of free services with the approach of using software systems to solve our daily organizational problems.